Game changing mashup of VHF, DSC, AIS, GPS, and vessel monitoring by Vesper Marine and the Cortex V1 leads the way in bringing communications functionality literally to your touch screen fingertips. This blazes the trail for feature upgrades at a pace never before seen for one of the most used tools on the bridge.

Mom says, "Wash Behind Your Ears!"

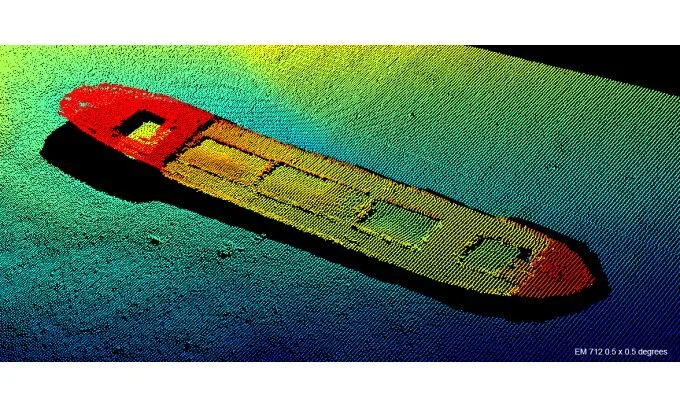

Multi-beam Advantage

Every now and then, something comes along that really is a game changer. In recent history, that has been the introduction of CHIRP fish finders and solid-state RADAR with processing capability like DOPPLER shift detection. It is time for the next major advance. Welcome, Multi-Beam Transducers!

Transducer Installation

The most critical factor in how a fish finder performs is the installation of the transducer element. Even the best electronics cannot overcome the laws of physics, so proper installation of the transducer will allow performance to meet equipment specifications. Any deviation from perfect starts to impact this performance.

Fishfinder; What do I see?

How to interpret a fish finder can be a long topic of discussion. Understanding how they work helps understand what they are trying to tell us. Times have changed and so has the technology. What used to be a simple flashing light is now a data rich display with hidden clues that give far more information than meets the eye.